How One Standardised CAD System Reduces Sample Rounds in Activewear Manufacturing

- demitracatleugh

- Dec 28, 2025

- 3 min read

The Pain Behind Endless Sample Rounds

If your team is constantly stuck in sampling cycles, the problem isn’t your factory it’s your files. Most founders assume misaligned prototypes come from poor communication or manufacturing constraints. But in activewear, the real bottleneck is upstream: designers working from inconsistent CAD logic. When every block, proportion, and seam is drawn differently, factories are forced to interpret your sketches. And interpretation always leads to variation the number-one driver of repeated sample rounds.

Why Activewear Teams Fall Into the Re-Sampling Trap

Activewear development is precision-based. Seam placement affects stretch. Panel geometry affects performance. Even one millimetre can change how a garment behaves.Yet inside many growing teams (10–300 employees), designers are working from entirely different starting points.

Different blocks.

Different annotation rules.

Different approaches to proportion and seam logic.

This inconsistency forces the factory to guess which interpretation is “correct.” A waistband drawn as a visual aesthetic line might look identical to a construction line but behave very differently once sewn. A block that isn’t standardised across the team will lead to slight proportion shifts that compound across sizes.

The root cause isn’t talent. It’s unstandardised CAD systems and misaligned drawing logic. Without one systemised visual language, teams unintentionally create ambiguity and ambiguity is the biggest predictor of multiple proto rounds.

Onboarding adds to the issue. New designers adopt their own habits; freelancers submit their own versions; older files get repurposed with slightly altered logic. Over time, the CAD archive becomes a tangled ecosystem where nothing matches.

The Cost of the Problem: Time, Fit, and Lost Revenue

Inconsistent CAD files don’t just slow development they compound operational costs.

Across GCC activewear teams, audits show that up to 40% of development time is lost not in production, but in correcting misinterpretations created by unclear files.

That delay flows through the entire chain:

More sample rounds (each costing weeks + freight + factory time)

Fit drift across styles and categories

Unpredictable approvals, delaying marketing, launches, and buying cycles

Team fatigue, as designers spend hours redrawing what should have been standardised

When every sampling round adds 2–4 weeks to a timeline, losing even one round can make the difference between launching on time, or missing your market moment entirely.

How the Modular Precision CAD System™ Fixes It

The Modular Precision CAD System™ is designed to eliminate the root cause of sampling inconsistency: variable drawing logic.

Instead of each designer building their own interpretation of a block, the system provides:

✔ One unified drawing architecture

Every line, seam, panel, and proportion follows the same logic whether drawn by one designer or twenty.

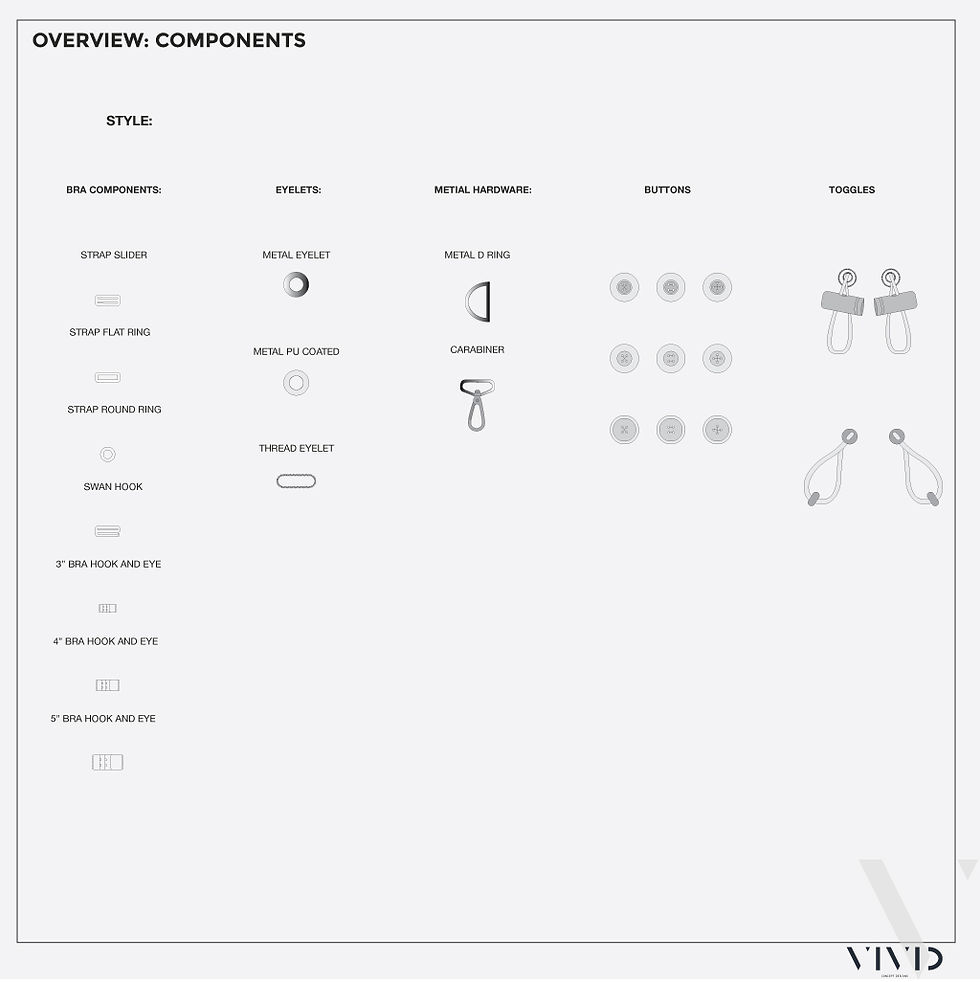

✔ Standardised modular blocks

Tops, bottoms, layers, support structures, and performance panels are all built on a consistent framework. Update a block once → the entire category follows suit.

✔ Optimised annotation rules

Clear, production-ready callouts eliminate ambiguity, ensuring factories understand construction intent instantly.

✔ Category-specific logic for activewear

Compression, recovery, gussets, mesh placements, seam reinforcement all systemised for clarity and precision.

✔ Factory alignment built-in

Factories receive clean, consistent drawings that require interpretation zero times reducing the need for re-samples caused by misreads.

By removing variation at the design stage, teams drastically reduce sampling loops.

Brands using the Modular Precision CAD System™ report:

Shorter sample cycles

Fewer fit corrections

Cleaner communication with production partners

More predictable product outcomes across ranges

Why Leading GCC Brands Are Systemising Now

Activewear brands across Dubai, Riyadh, Doha, and Kuwait are scaling faster than ever but with growth comes complexity.Teams expanding from 5 to 50 designers are realising that creativity alone can’t sustain speed. Precision systems are the new competitive advantage.

Brands adopting the Modular Precision CAD System™ are reporting fewer sampling rounds, stronger factory alignment, and tighter fit consistency across ranges — especially in highly technical categories like leggings, compression tops, and performance layers.

Start Reducing Sample Rounds Today

The brands growing fastest in 2025 aren’t just designing better products they’re designing better systems.

If your goal is fewer prototype rounds, faster approvals, and predictable quality across your range, the solution begins long before production.It begins with one standardised CAD language.

Discover the Modular Precision CAD System™ the activewear industry’s design language standard.

Start here → 🔗 vividconceptsdesigns.com

For bespoke adoption support and team onboarding, connect directly with VIVID CONCEPTS™ → 🔗 vividconceptsdesigns.com/contact

Comments