The Hidden Cost of Inconsistent CAD Files in Activewear: Fit Errors, Delays, and Lost Margin

- demitracatleugh

- Nov 30, 2025

- 3 min read

The Frustration Every Activewear Team Knows

Why does your team spend hours redrawing the same base block only for the factory to misinterpret it again? Why do two designers produce two completely different versions of the same legging, even when working from the same brief? And why do sampling rounds drag on, even when the design “should” have been clear?

For most growing activewear brands, the issue isn’t the designers. It isn’t the factory.It’s the CAD files and the inconsistency buried inside them.

Root Cause: Why CAD Files Become Inconsistent

Activewear product development relies heavily on technical precision. But in most teams, CADs are built on years of legacy habits, designer-specific drawing styles, and undocumented construction logic. Over time, the system becomes chaotic even if the team is talented.

Here’s what typically causes the breakdown:

No shared design logic: Each designer draws proportion, seam placement, or panel shaping differently. The factory reads these differences as different fits.

Legacy files evolve without documentation: One designer edits a block. Another tweaks it. A third adapts it for a new season. Soon, there are five versions of what should have been one standard.

Inconsistent onboarding: New designers pick up CAD habits from whoever trained them, not from a unified workflow. “This is how I draw it” becomes the default.

Unaligned internal tools: Line weights, stitch representations, curve logic, and panel spacing vary from file to file small inconsistencies that snowball into production errors.

None of this is intentional. But it creates a design environment where clarity relies on instinct, tribal knowledge, and guesswork not systems.

The Cost of the Problem: Lost Time, Lost Margin, Lost Confidence

When CAD files are inconsistent, inefficiency spreads through the entire product lifecycle. Most brands underestimate this problem but it shows up in the numbers.

Up to 40% of activewear development time is lost to redrawing, correcting, clarifying, or re-explaining sketches.

Sampling rounds increase by 1–3 cycles simply because factories cannot interpret mismatched construction logic.

Fit variation becomes common, especially across seasonal blocks that should remain stable.

Margins shrink when delays force air shipments, last-minute pattern corrections, or rushed approvals.

This isn’t a design issue. This is a systems issue and it compounds as teams grow from 3 to 30 designers.

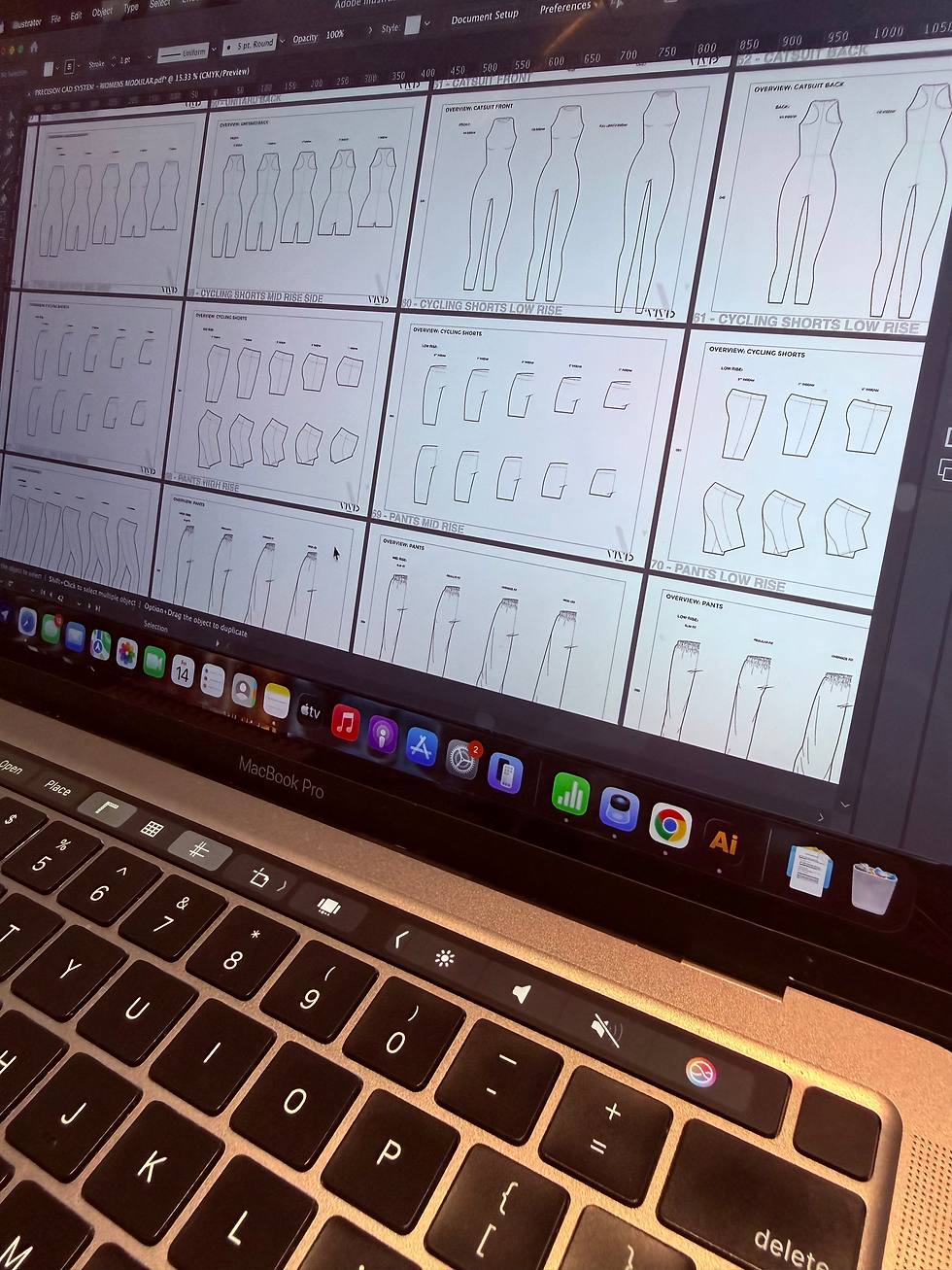

Solution: How the Modular Precision CAD System™ Fixes It

The Modular Precision CAD System™ was built for one purpose: to bring clarity, consistency, and precision back to activewear product development. It replaces fragmented CAD logic with a unified, scalable design language that every designer and every factory can understand without interpretation.

What makes it unique:

1. Standardised Drawing Logic

Every curve, stitch, panel, and proportion follows a consistent system. No matter who draws the style, the file logic stays identical eliminating misreads.

2. Modular Fit Blocks

The system includes pre-engineered base blocks designed specifically for activewear. Designers pull from the same foundations, ensuring consistent fit across categories and seasons.

3. Production-Ready Line Art

Line weights, stitching representation, notches, panel intersections, and construction callouts are all unified reducing factory confusion and approval delays.

4. Faster Approvals & Fewer Samples

When design logic is consistent, factories produce the intended fit the first time. Brands using systemised CADs see up to 30% fewer sample iterations.

5. Seamless Team Onboarding

New designers learn the system, not someone’s personal style. Teams scale without losing precision.

Why Leading GCC Brands Are Systemising Now

As activewear competition intensifies across the UAE, Saudi Arabia, Qatar, and Kuwait, brands are realising that speed alone won’t win clarity will. Teams working remotely, scaling quickly, or managing multi-factory production cannot rely on instinct or informal CAD logic.

Systemisation is becoming the competitive advantage for brands expanding product lines or entering new categories.The Modular Precision CAD System™ is already used by teams seeking:

Greater fit consistency

Fewer approval cycles

Stronger factory relationships

Faster design-to-production timelines

The brands growing fastest in 2025 are the ones building systems not just products. Your CADs are the foundation of your entire design-to-production workflow. When they’re inconsistent, everything slows down. When they’re unified, everything accelerates.

If your team is ready to eliminate fit discrepancies, shorten sampling timelines, and build a design language that scales with your brand, start here:

➡️ Discover the Modular Precision CAD System™ https://www.vividconceptsdesigns.com/cad-templates-activewear

For custom guidance or team onboarding support, contact us directly:

Systemise your design language. Protect your margin. Design with precision.

Comments