Why Activewear Teams Waste 40% of Development Time and How Standardised CAD Systems Fix It

- demitracatleugh

- Nov 23, 2025

- 3 min read

Why do activewear teams spend hours redrawing the same base block… only for factories to misinterpret the design anyway?

Why do approvals stall, tech packs contradict each other, and sample rounds increase despite experienced designers and clear intentions?

If you’ve ever looked at your team’s workflow and thought, “How is everything taking this long?”, you’re not alone.

Across the GCC, growing activewear brands face one core operational truth:

Up to 40% of development time is lost to CAD inconsistency.

Not creativity.

Not innovation.

Inefficiency.

Why This Happens in Activewear Teams

Most activewear teams don’t suffer because of talent gaps they suffer because the tools and systems around the talent aren’t standardised.

Three silent issues drive the majority of wasted development hours:

1. Unstandardised CAD Systems

Each designer creates drawings based on their own habits:

One uses heavy outlines

One uses thin stroke logic

One adds panel seams

One doesn’t

One uses US letter sizing

One designs on A4 with no grid system

On their own, none of these choices are wrong.

But together, they create completely incompatible drawing languages.

So factories, merch teams, and junior designers all interpret these drawings differently.

2. Misaligned File Logic

Grow a team from one designer to three and suddenly:

CAD libraries don’t match

base blocks don’t align

the same legging exists in five versions

nobody knows which version is “final”

This leads to re-drawing, re-formatting, re-explaining, and constant re-checking.

3. Inefficient Onboarding

Without systemised CAD standards:

hiring becomes slow

juniors take months to onboard

senior designers become “bottlenecks” because only they understand the correct logic

As teams scale (especially across UAE, KSA, and Qatar), inconsistency compounds.

The result? Designers spend more time aligning files than designing product.

The Cost of the Problem

CAD inconsistency doesn’t just look messy, it has measurable financial impact.

Here’s the true cost:

20–40% of development time is lost to re-drawing, re-formatting, and clarifications

Sampling rounds increase by 1–3 cycles, adding thousands in unnecessary cost

Approvals slow down, delaying drops and reducing agility

Fit inconsistency emerges, damaging brand trust

Factories lose clarity, leading to misinterpretation and communication loops

For GCC brands working with fast retail cycles and higher expectations from premium customers, this isn’t just inefficient

it directly erodes margin and slows growth.

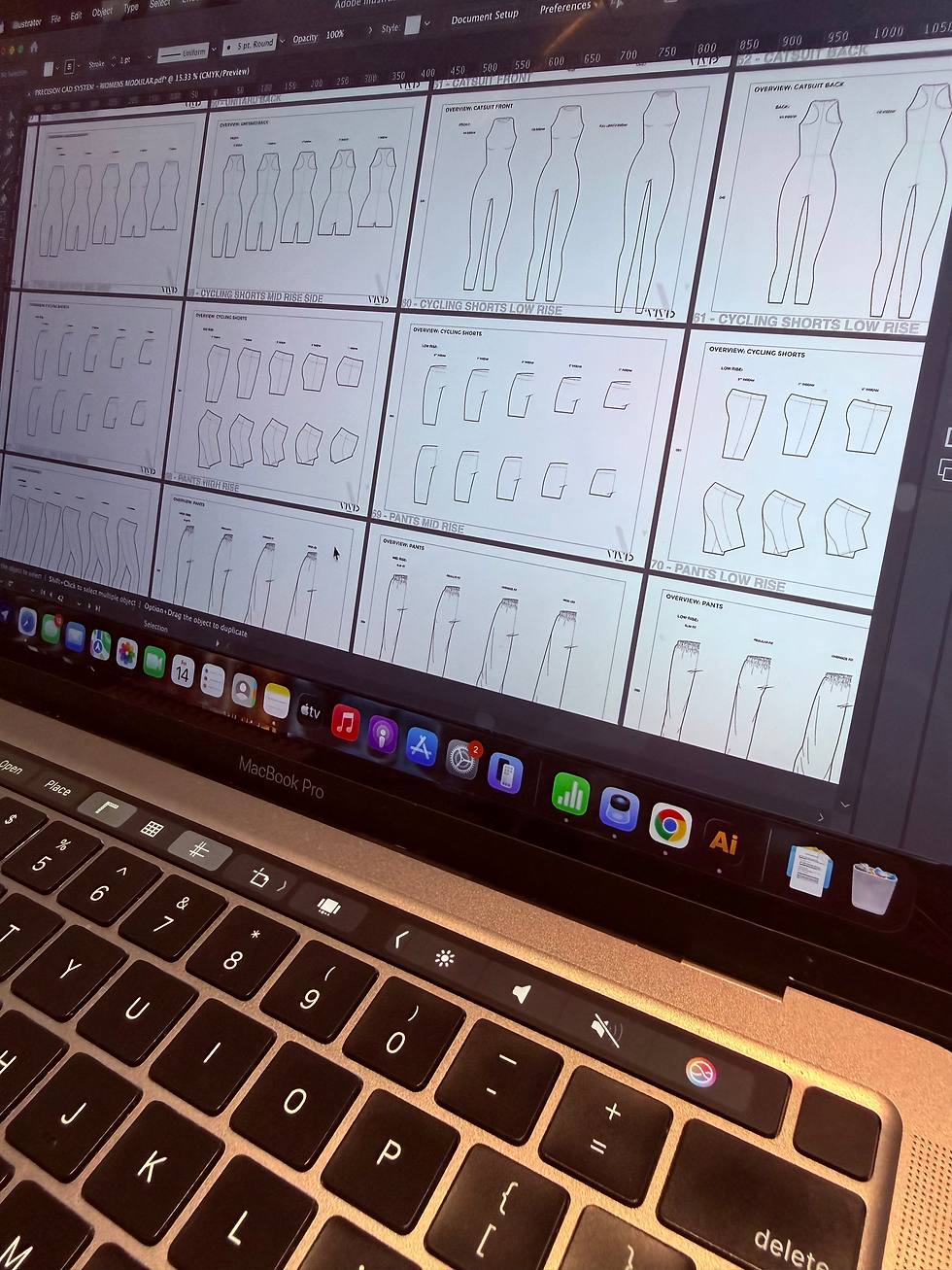

How the Modular Precision CAD System™ Fixes This

The Modular Precision CAD System™ was engineered specifically for fashion and activewear brands scaling from 5 to 50 designers across the GCC.

It eliminates design inconsistency at the source by introducing one unified drawing language for your entire team.

1. Standardised Design Logic

Every line weight, seam, construction detail, and layout is already systemised:

Consistent stroke hierarchy

Precise annotation logic

Pre-structured page layouts

Drawing language aligned with factory interpretation

Your designers stop debating drawing style and start designing product.

2. Modular Fit Blocks

Instead of every designer redrawing the same base shapes, the system includes:

master legging blocks

performance tops

sports bras

jackets

shorts

adjustable modular overlays

All blocks interlock with identical logic meaning fast changes, fewer errors, and clear fit consistency across collections.

3. Rapid Onboarding

Junior designers, freelancers, and new hires can produce CAD-ready drawings from day one.

No more months of alignment.

No more correcting drawing logic.

No more “This isn’t how we draw seams here.”

4. Factory-Ready Output

The system speaks the language your factory actually needs:

Clear seam construction

Correct grainline logic

Consistent call-outs

Optimal line precision for sampling

That means faster approvals, fewer clarifications, and reduced sample rounds.

Proof & Authority: Why Leading GCC Brands Systemise Now

Across the UAE, Saudi Arabia, and Qatar, brands scaling in 2025 are moving away from talent-led workflows and toward system-led precision.

Why?

Because scaling teams, launching more drops, or working with multiple factories requires uniformity not improvisation.

Brands that implement CAD standardisation early see:

Faster approvals

Reduced sampling cost

Improved cross-team alignment

Fewer production errors

Higher-quality design output

The Fastest-Growing Brands in 2025 Are Systemised Ones

The activewear brands growing fastest in the GCC share one thing in common:

They’ve standardised their design language.

If you’re scaling your team…

If your approvals are slowing down…

If your factory keeps misinterpreting your drawings…

If your designers are redrawing the same CADs every week…

Then it’s time to implement the system built for growth.

Discover the Modular Precision CAD System™: the activewear industry’s design language standard.

For bespoke guidance:

Comments