Why Your Designers Are Redrawing the Same Blocks Every Week and How to Stop the Cycle

- demitracatleugh

- Dec 7, 2025

- 3 min read

The Frustration No One Has Time For

If your design team is constantly redrawing the same base blocks leggings, bras, tanks, shorts you’re not alone. Almost every activewear brand hits this wall. One designer updates a detail, another works from an older template, the factory requests a cleaner CAD, and suddenly you’re burning two full days on something that should take 20 minutes. It’s draining, inefficient, and completely avoidable. But the cycle continues… until you systemise it.

Root Cause: It’s Not Your Designers, It’s the System

Here’s the truth most product teams don’t realise: designers aren’t redrawing because they want to. They’re redrawing because the system forces them to.

Activewear teams across the GCC often work with CAD files accumulated over years old versions, mixed logic, inconsistent line weights, and template files that were never built as actual systems. They were built as one-off drawings, reused long after they stopped being accurate.

Different designers draw seams differently.Annotation logic varies.Fit blocks evolve but the library doesn’t follow.New hires don’t know which template is the “correct” one. Factories request clarity because the CADs don’t read consistently.

And when there’s no unified, standardised drawing language, every new style becomes a reinvention of the wheel. Designers compensate by redrawing from scratch because it feels faster than trying to “fix” a broken file.

This isn’t a human problem.It’s a structural one created by scattered design assets, zero standardisation, and outdated CAD habits that simply don’t scale.

The Cost of This Hidden Inefficiency

Redrawing might feel like a normal part of design work, but the hidden cost is significant:

Up to 40% of development time is lost to CAD inconsistency

Sampling delays multiply because factories misinterpret unclear drawings

Fit inconsistency increases across drops and seasons

Teams experience burnout from repetitive manual tasks

New hires onboard slowly, relying on tribal knowledge rather than systemised structure

Founders absorb the financial hit through duplicated samples and padded timelines

Across a 12-style activewear drop, this inefficiency can cost teams 40–80 extra hours time that should be spent on refining fit, developing new silhouettes, or managing production deadlines.

Solution: How the Modular Precision CAD System™ Stops the Redraw Cycle

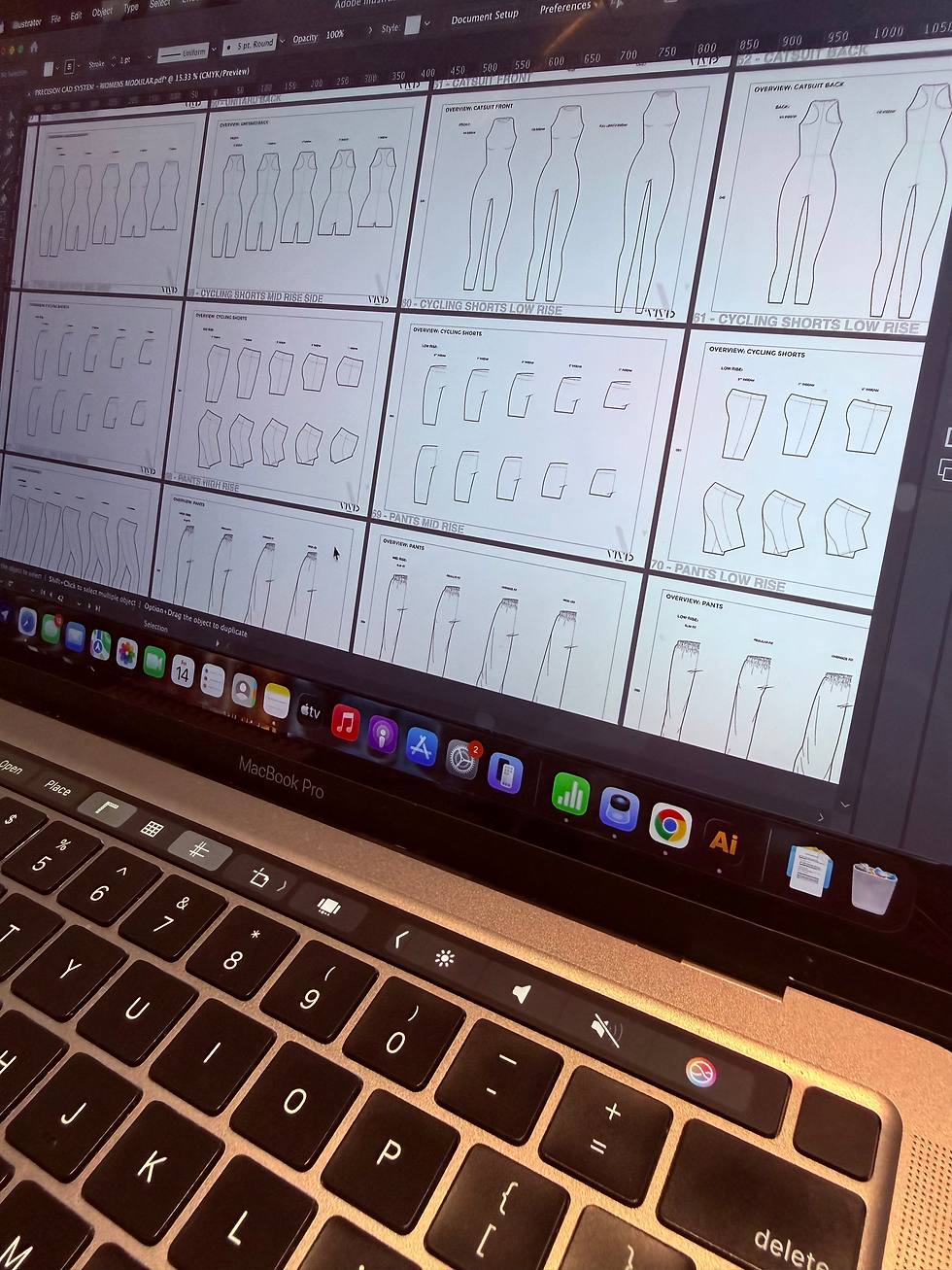

The Modular Precision CAD System™ was created for one reason to eliminate unnecessary redraws by giving activewear teams a single, unified, precision-built CAD ecosystem.

Here’s how it breaks the cycle:

1. Standardised Drawing Logic

Every seam, line weight, annotation, stitch detail, and construction mark follows one engineered language.No guesswork, no variations, no personal drawing habits creeping in.

2. Modular Building Blocks

Instead of starting from scratch, designers pull from an integrated library of

pre-engineered blocks:

Leggings (multiple rises)

Sports bras

Tanks

Sleeves

Hems

Gussets

Waistbands

Inserts & panels

Every module slots together cleanly without distortion, removing the need for redrawing core shapes.

3. Precision Geometry = Factory Clarity

Factories read your CADs faster because every detail is communicated the same way across every style and every designer.

4. Faster Onboarding for Growing Teams

Instead of months learning “how your brand draws,” new hires plug straight into a structured system.

5. Built Specifically for GCC Activewear Brands

Based on patterns, silhouettes, and technical expectations of the UAE, Saudi Arabia, Qatar, Bahrain, and Kuwait markets where performance, modesty options, and brand refinement matter.

Proof & Authority: Why Leading GCC Brands Are Systemising Now

Across the GCC, brands are shifting from ad-hoc design workflows to precision-driven systems because growth exposes inconsistency instantly. More designers, bigger assortments, and faster seasons demand clarity not more manpower.

Teams using the Modular Precision CAD System™ report:

40–60% faster approvals

Fewer sample iterations

Higher consistency across drops

Cleaner handovers to production teams and factories

Systemisation isn’t a trend, it’s becoming the baseline requirement for any brand scaling beyond 5 designers.

CTA: Take Control of Your Design System (100 words)

The brands growing fastest in 2025 share one thing:They’ve stopped relying on inconsistent files and they’ve standardised precision.

If your team is stuck in the redraw cycle, constantly reinventing base blocks, or wasting time fixing outdated files, it’s time to operate differently.

Discover the Modular Precision CAD System™ the activewear industry’s design language standard.

➤ https://vividconceptsdesigns.com/cadsystems Or get in touch

Systemise once. Scale always.

Comments